It’s hard to imagine that pest control practices would involve electricity or other types of stored energy. In fact, Lock Out/Tag Out (LOTO) is used quite frequently in pest management work. As insect hunters, mice chasers, squirrel excluders, and spider ninjas, a variety of electrical and pneumatic tools are used, and LOTO procedures are followed for safety of the workers.

When contracted for termite work, pest pros use large gas or electric powered sprayers. These rigs also have wiring attached to a battery or spark plugs, and springs in the pull cord winding mechanism. Preventative maintenance (PM) can be performed as needed, but with safety protocols in place.

Fuel should be emptied, and applicable wiring to the ignition source should be disconnected. The spring to the winding mechanism should be fixed in a stationary position to prevent accidental turning. No one wants to lose a middle finger.

The person working on the spray rig is close enough to know if someone might try to start the rig, so it may not be necessary to use a locking hasp for security. Safety cones or hazard tape could suffice to notify others that work is being done in that area. Only allowing access for necessary personnel will reduce many risks.

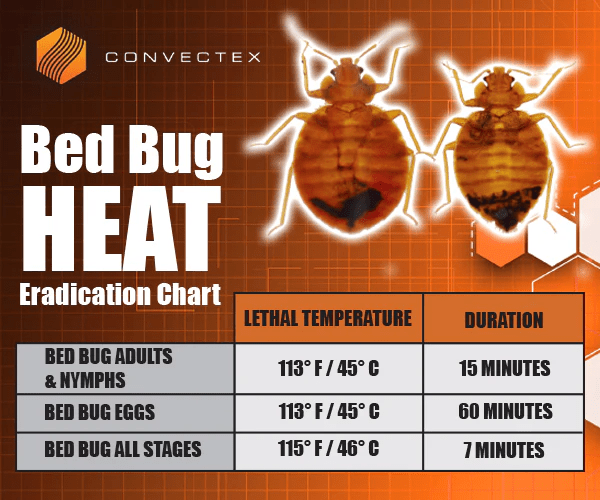

Those who perform bed bug work often use electric or propane powered heat equipment. Maintaining quality service standards means making sure the heaters work when they should. Cleaning heat units doesn’t have to be complicated, but it does require some expertise and safety.

It’s a feasible option to place a plug cover lock on the cord to a heating unit. If these get plugged into an outlet, the fan motor and heating element could turn on. The employee doing PM could be injured by the fan or sustain serious burns from the heating element, both within the unit. What a terrible way to get a tan.

Pest management personnel who specialize in wildlife work and exclusion use a wide array of equipment, that if not used properly, can have serious consequences. Pnuematic staplers, brake presses, shears, scissor lifts, and drills require stored energy to be blocked or released before maintenance can be done.

Pnuematic tools and machines can be disconnected from the energy supply by releasing the air pressure that makes it work. Unplugging drills that are corded, or removing the battery pack from others is usually sufficient. Larger tools like a press brake or a shear can be compact enough to fit in a service vehicle. Some can be used manually, but larger equipment is usually electrical will have a designated breaker that need to be disconnected.

While not everything requires a padlock or a tag when maintenance is being performed, it’s a good idea to have some written procedures in place. Such as: for simple tool with a plug, sit on the plug so no one can attempt to put it in an outlet. Or making sure the air source for pneumatic staplers is not within arm’s reach and turned off so you are not tempted to fire a test round.

When LOTO is used to secure equipment, the person who placed the LOTO device is the ONLY one who can remove it, except for a few instances. Employers are the ones responsible for giving their staff he proper training on Lock Out/Tag Out procedures, but information can be found from various resources.

Your personality is electrifying enough. There is no need to add shock value.

Discover more from Pest Control Chatter

Subscribe to get the latest posts sent to your email.